Flow Measurement Devices Pdf

Accurate flow measurement is very important for proper and equitable distribution of water among water users.

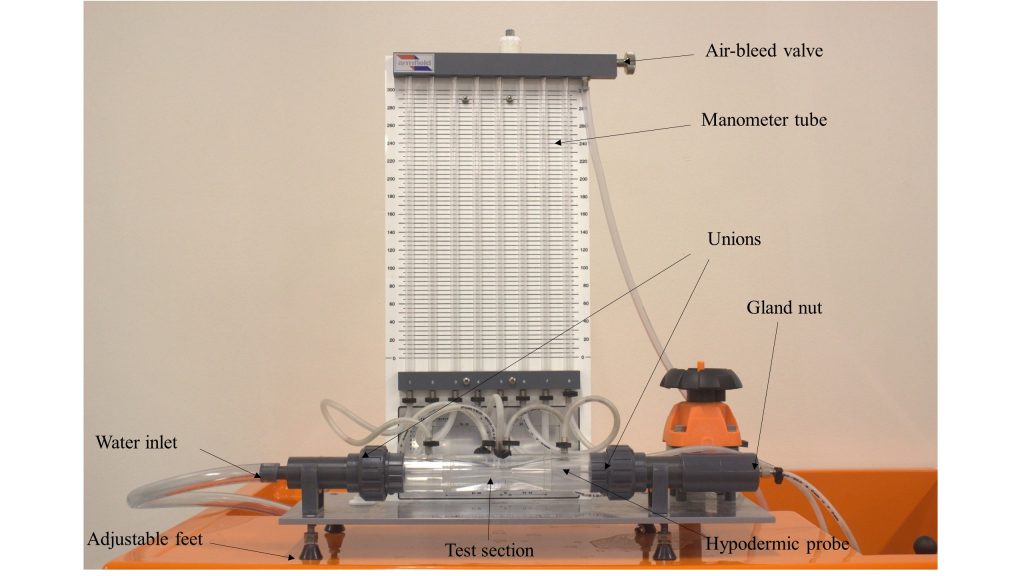

Flow measurement devices pdf. Friction pressure drop packed screens 3. Fixed restriction variable head type flow meters using different sensors like orifice plate venturi tube flow nozzle pitot tube dall tube quan. Industrial flow measurement industrial flow measurement basics and practice d184b075u02 rev. In its simplest form the device consists of a short converging section leading to a throat and followed by a diverging section.

Pressure drop devices based on bernoulli principle a venturi b orifice plate c pitot tube 2. 1 1 types of flow measurement devices fluid flow devices fall into a number of device categories as well as fluid classes. Where a measuring accuracy of 5 is sufficient these lengths should be a minimum of ten and three equivalent pipe diameters respectively. Cryogenic flow metering techniques 1.

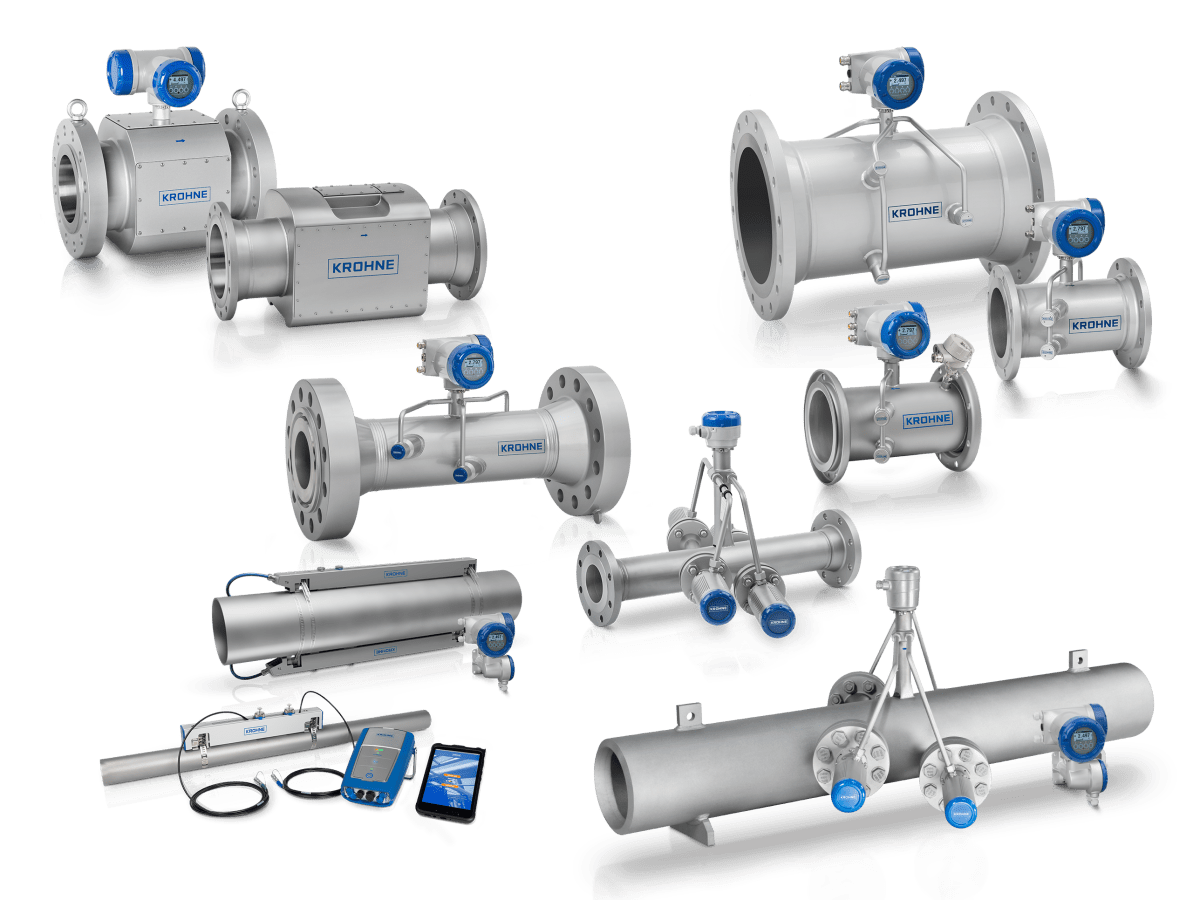

Measuring the flowrate and quantities of flowing fluids are described and compared. Numerous practical details provide the user with valuable information about flow metering in industrial applications. In general we can split the fluids into two classes. Flow measurement pdf 1.

Acoustic flow meters based on doppler effect 5. Types of flow meters and their applications flow measuring device 1. Flow measuring devices are generally classified into four groups. Flow measurement devices increasing utilization and the value of water makes the understanding of water measuring techniques important and necessary.

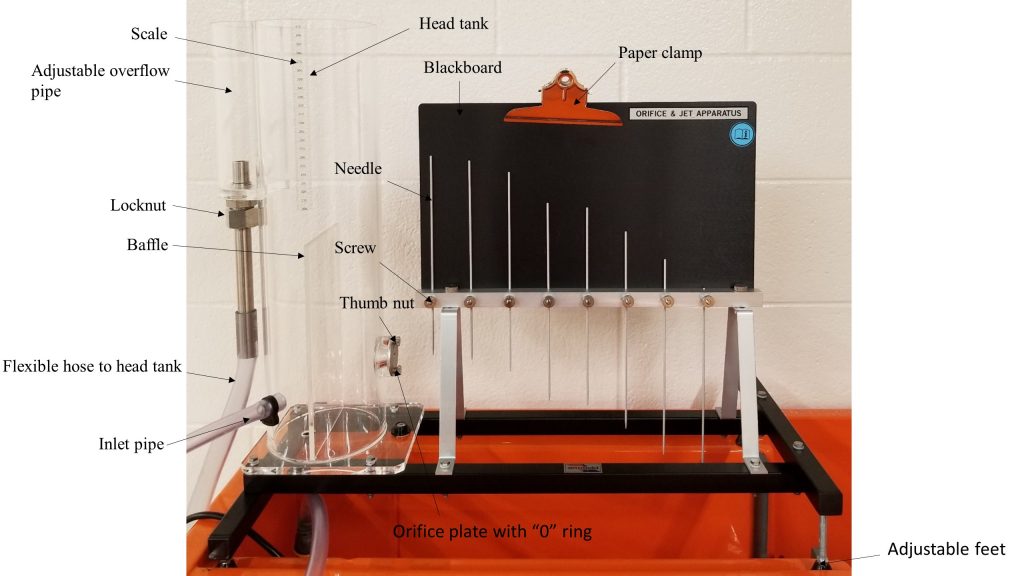

A venturimeter is a device meant for measuring the quantity of a liquid flowing through a pipe. Because they are used for domestic water measurement piston meters also known as rotary piston or semi positive displacement meters are the most common flow measurement devices in the uk and are used for almost all meter sizes up to and including 40 mm 1 1 2 in. 2 industrial instrumentation c 8 n ind book1 1 they are. Turbine flow meters where frequency velocity 6.

The flow measuring device including flow measurement valves should be positioned upstream of any associated valve and installed with a reasonable length of straight pipe upstream and downstream of the device. Mechanical type flow meters. Information concerning the volume of available water is very helpful in planning. Crude methods of flow measurement but as you will see these crude methods are still in use today.

The piston meter operates on the principle of a piston rotating within a. The differential pressure flow meter is based on the bernoulli equation where the pressure drop and the further measured signal is a function of the square flow speed. In a differential pressure drop device the flow is calculated by measuring the pressure drop over an obstructions inserted in the flow.

.jpg)